In Russia, the Additional Rules on Stimulation of Commercial Shipbuilding and Navigation allowing ship owners to choose ship experts at their option are introducing. It gives an impetus to the development of shipbuilding segment.

One of the first shipyard established in the south of Russia.is in the Aksay river outlet where flat-bottomed vessels were built.

History

Active stage of Aksay shipreparing shops development started. Wooden fleet was replaced with metallic one, The shops were fitted with necessary equipment for metal working operations. The electric welding was implemented.

The shops have been included into Don-Kuban river shipping company administration of MRF of the USSR.

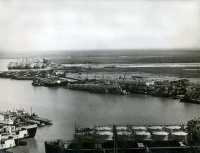

Volga-Don shipping canal has been built – Rostov-on-Don becomes the port of five seas, servicing “river-sea” vessels within all-year navigation. Aksay’s ship repairing shops passes from the third-class to first-class category. Number of workers increased to 1,000 persons. About 120 fleet units have been handed over to the shops for economic-technical maintenance. They were joined to the Volga-Don river shipping company of MRF of the USSR.

Ship repairing shops were reorganized into Aksay Repair-Maintenance Base of Fleet of the II Category having become structural subdivision of the Volga-Don river company. New stage of enterprise development starts: 150 small-tonnage vessels were handed over to the repair-maintenance base balance, new equipment, mechanizing process of vessels hoisting onto the shore were implemented.

The Volga-Don shipping company made a decision on establishing of large shipbuilding - shiprepairing plants on the Aksay repair-maintenance base in downstream Don river. The process of Aksay fleet repair-maintenance base (RMB) large-scale reconstruction started. Twenty hectares of inundable lands have been provided for the project. To prevent flowage during flood the provided area has been 3.5 m raised by sluicing 470 tons of sand. In the ensuing years, 100-t dock-pontoon, saw mill and new shops equipped with metal-working rolling-and-bending machines have been placed in operation. Labor productivity increased by forty percent.

Aksay RMB rises to a new level: SLIPWAY G-300 with 8 inclining paths for hoisting and repair of vessels up to 100 m length, and up to 1600 tons cargo carrying capacity and oxygen plant have been put into operation. 25-ton crane Gants and 20-ton frame crane have been procured and mounted in slipway. In the ensuing years, 120 m length outfitting quay wall was built, three-span 4000 m2 area storehouse steel structures have been procured and mounted along with 20-t crane “Al’batros”, premises were enclosed with concrete plates and 30 ha area attached to the plant at the left bank. Overall plant area, considering right bank area was 32.5 ha. Building of 120 m harbor wall was completed in the area of wood-sawing complex. ‘Bachelorette’ sections per 57 flats have been put into service in settlement Vodnik. Aksay RMB becomes urban enterprise.

The Volga-Don river shipping company was divided into seventeen independent enterprises. On the basis of the Aksay RMB, the Aksay Shiprepairing Plant has been found as a part of the River Fleet Department under Ministry of Transport of RF. All RMB basic funds have been handed over to the plant except for floating workshop and M/V RBT, as well as all territory excluding aquatic area and narrow foreshore in the area of floating workshop mooring site.

The ferry craft “Dorozhnik” in Starocherkassk town was built. The plant performed vessel re-equipment successfully. River vessels like DON, VOLGA-DON, ZHIGULYEVSK, OMSKY, SIBIRSKY, STK were re-equipped into vessels of combined navigation “river-sea”, and dry cargo ships like ST, OKA – into tankers with exit to littoral Azov sea ports. In the ensuing years, about 100 vessels have been re-equipped. Three-storied 500-seats administration and amenity building was built on the right bank and winter garden as well. Premises for repair of prop-rudder systems, sections for pipeline, fitter's and assembler's sections, electric section, compressor section, hull-preparation section, 11 store units of general depot, main gate security office, overpass complex over river Aksay have been built. Two in number of 20-t crawler-mounted cranes, electric welding and metal-cutting equipment, barrel-turning machine for processing of up to 10 m length propulsion shafts were procured.

Next development spiral of enterprise started with building of three-span shop equipped with NC plasma arc cutting machine, overhead crane and hydraulic press.

The same year, modernization of SLIP was carried out taking into consideration servicing peculiarities of new generation of vessels with length to one hundred forty three meters and lifting capacity up to seven thousand tons and dock weight up to three thousand tons.

Corporate identity of JSC SSRZ MIDEL was rebranded. Our company changed its image in a big way. Logotype, color scheme, business strategies, competition policy and standards have been changed. Independent subdivisions appeared in our company the goal of which shall be maximum qualified and prompt client need satisfaction with genuine care about its convenience.

- 1

- 2